For Monitoring Process Capability We Use Which Graph

When to Use Pp Ppk Cp and Cpk. L S L Lower Specification Limit.

3 4 6 Assessing Process Capability

σ estimated variability of the process standard deviation.

. If we have a continuous data type then we can use 3 types of Control Charts ie. Pp and PPk are used for Process Performance. The standard method is from a control chart where the data is collected over a period of time.

The R chart indicates whether the subgroup-to-subgroup variation is in control. Record the measurement data and plot this data on a run-chart and on a histogram as shown in the picture on the right. Capability indices predict process behavior.

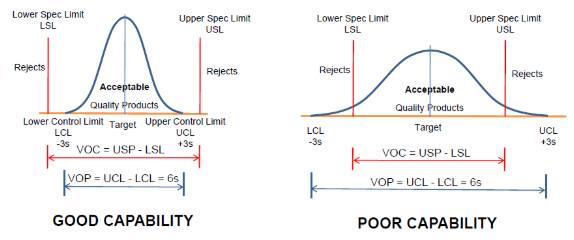

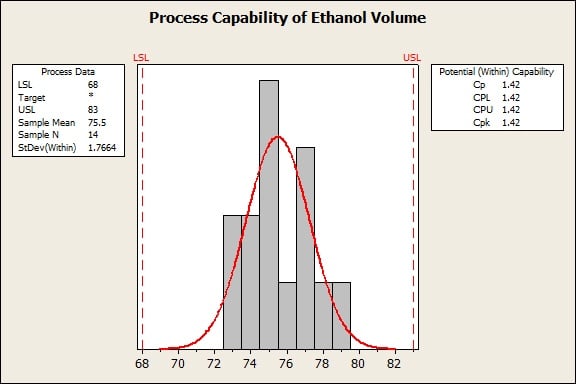

Cp is the process capability. Plot the Upper Spec Limit USL and Lower Spec Limit LSL on the histogram and calculate the Spec Width as shown below. Generally you use this when a process is under statistical control.

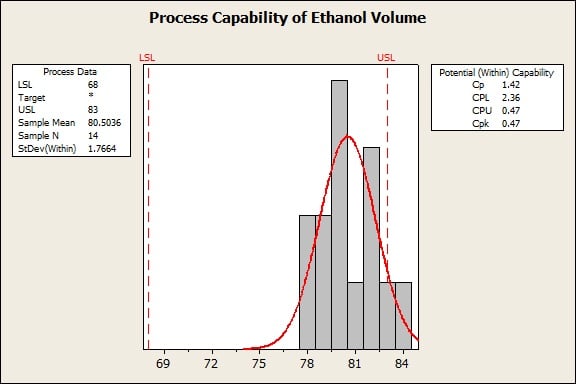

It refers to how well the process can satisfy the specifications. A Shewhart chart named after Walter Shewhart from Bell Telephone and Western Electric monitors that a process variable remains on target and within given upper and lower limits. Cpk stands for the Index.

When used to monitor the process control charts can uncover inconsistencies and unnatural fluctuations. It does not track anything else about the measurement such as its. Process capability index Cpk is a statistical tool to measure the ability of a process to produce output within customers specification limits.

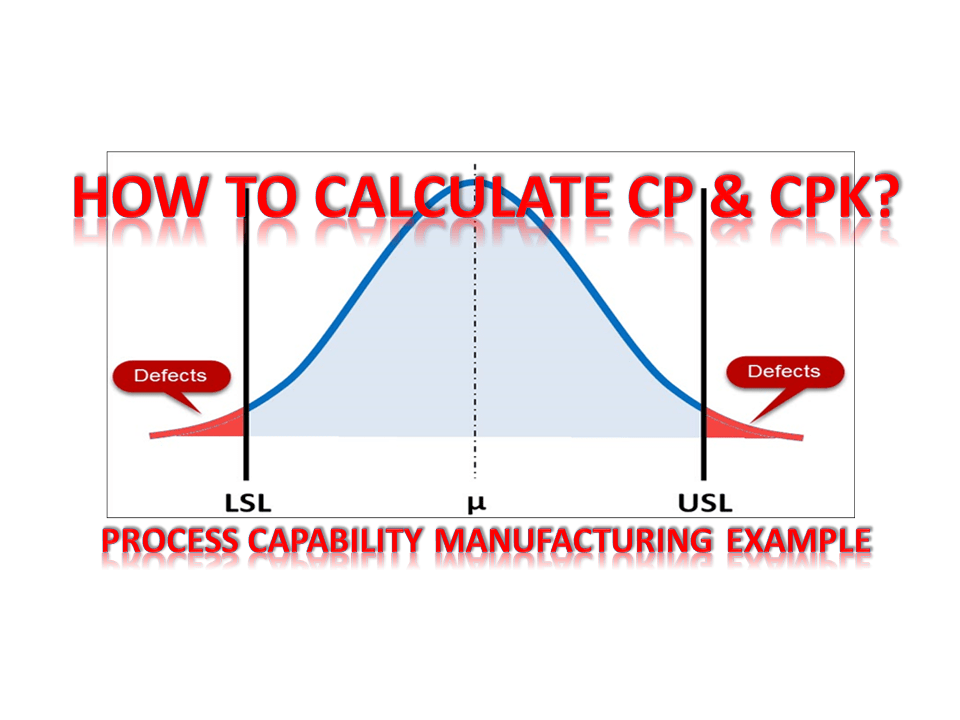

If the histogram falls within the specification limits then the process is capable. If we have a discrete data type then we use the 4 types of Control Charts. Cpk Process Capability Index 166.

To understand what a process is doing and what it can do we need both the Cp and Cpk indices. Process capability uses the process sigma value determined from either the Moving Range Range or Sigma control charts. C p m i n U S L μ 3 σ μ L S L 3 σ Where.

It answers the question whether the variables location is stable over time. μ estimated mean of the process. Cp and Cpk are used for Process Capability.

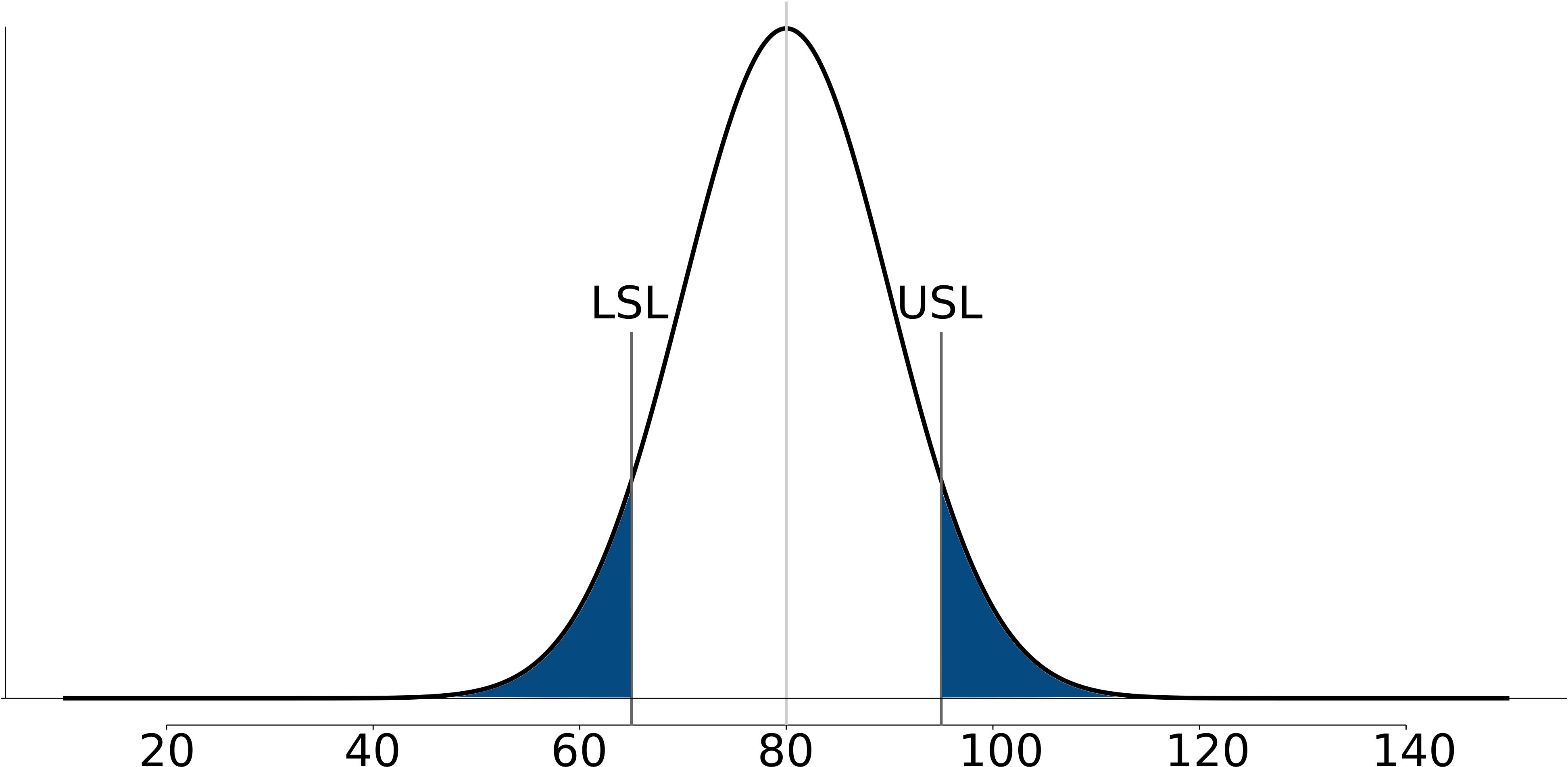

U S L Upper Specification Limit. Using the graph we can further evaluate process capability by comparing the spread or range of the product specifications to the spread of the process data as measured by Six Sigma process standard deviation units. Red points indicate subgroups that fail at least one of the tests for special causes and are not in control.

They represent the fit between the expected future production and the specifications. Cpk is used to estimate how close you are to a given targe. The larger the Cp index is the less likely it is that any unit manufactured in your process will be outside the defined limits.

The main difference between Pp and Cp on one side and Ppk and Cpk on the other side is whether we use complete set of data for calculation Pp and Ppk where we calculate real performance of the system or we use sample pre-production batch logical subgroups where we calculate capability of the process. I-MR Chart X Bar R Chart and X Bar S Chart. Control Charts are basically of 7 types as it all depends upon the data type.

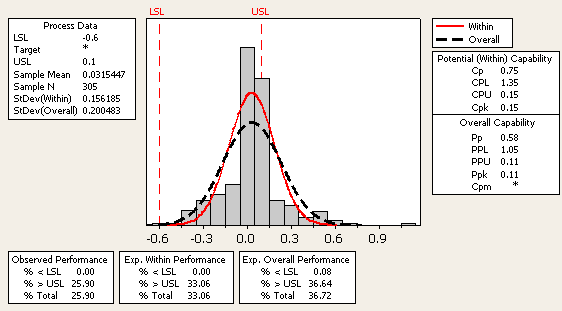

Process Performance Graph Four quadrant graph that assesses processes in term of stability and capability. This often happens with a mature process that has been around for a while. Note how the process is shifted below target and the process variation is too large.

Use an R chart to monitor the variation of a process and determine whether it is stable enough to perform capability analysis. Spec Width USL LSL. It measures how close your process is to the defined upper and lower limits compared to a reference optimal process.

Cp Process Capability 168. Statistical Process Control charts graphically represent the variability in a process over time. The R chart indicates whether the.

There are two ways to collect data for capability analysis. It is a monitoring chart for location. If data has been collected in this way the standard method for performing capability analysis is used.

Higher the value of process capability index C. P Np C and U Charts. This is illustrated in the graph below.

This is an example of. Use a capability chart. Calculate the Spec Width.

In simple words it measures producers capability to produce a product within customers tolerance range. A direct way to measure and make an analysis of the process capability. Consequently SPC charts are used in many industries to.

Graphically we assess process capability by plotting the process specification limits on a histogram of the observations. Goal Plot Graph for quickly assessing how processes are conforming to. Use an R chart to monitor the variation of a process and determine whether it is stable enough to perform capability analysis.

Cp Cpk Pp And Ppk Know How And When To Use Them

How To Measure Process Capability And Process Performance

Process Capability Analysis Download Cp Cpk Excel Sheet Template

Process Capability Index An Overview Sciencedirect Topics

Process Capability Part 2 Bpi Consulting

What Is Process Capability Spc 101 Infinityqs

6 1 6 What Is Process Capability

Cp And Cpk Statistics Process Capability Analysis Infinityqs

Getting The Most Out Of A Capability Analysis

Cp And Cpk Statistics Process Capability Analysis Infinityqs

3 8 Process Capability Process Improvement Using Data

Process Capability Cp Cpk And Process Performance Pp Ppk What Is The Difference

Process Capability Statistics Cp And Cpk Working Together

Process Capability Statistics Cp And Cpk Working Together

Process Capability Part 1 Bpi Consulting

Process Capability Part 2 Bpi Consulting

Process Capability Quality One

Step 4 Interpret The Graph Pattern And Cpk Value Process Capability Statistical Process Control Excel Templates

Comments

Post a Comment